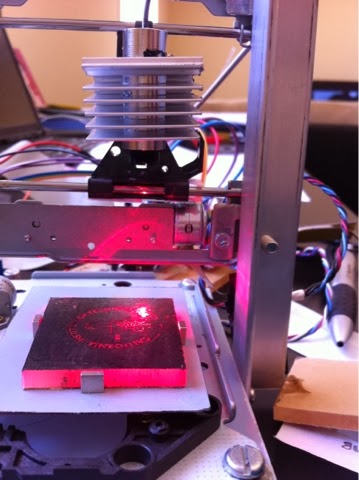

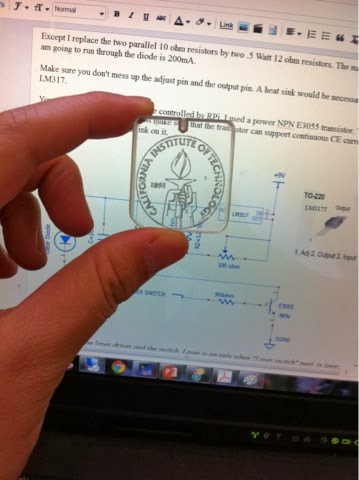

| Before you go any further, please take a minute to consider your eyes. You only have two of them, and they’re not replaceable. You need both for certain applications. Lasers are dangerous, and they can burn flesh: please be careful around them. And with that out of the way… I found this project on our forums, and it knocked my socks off. Daniel Chai has made something incredible with a Pi and parts salvaged from a pair of optical drives: a very low-priced, fine-resolution laser engraver. This differs from Arduino-driven engravers we’ve seen before: Daniel only uses a Pi, and he’s written his own control system, where his Python interprets G code and drives the stepper motors on both axes at the same time. Daniel says: The reason why I choose Raspberry Pi is: it is a much more powerful device than Arduino; it has a complete OS; the GPIO pins can be controlled by python, a more intuitive and simpler language than C (the disadvantage of python would be the slow speed); I don’t have to buy a separate controller for this project–I can use a single Raspberry Pi to do a lot of different things without reloading firmware. Most importantly, I have a Raspberry Pi but don’t have an Arduino right now! The most expensive parts of this project, namely the stepper motors and laser diodes, were salvaged from two old DVD writable drives which had been abandoned as e-waste. (DVD drives are much preferable to CD drives, which can be ultra-dangerous because their laser is an infra-red laser, invisible to the naked eye – don’t go poking around the innards of those if you value your eyesight.) Other parts of those drives are also used to make a tray to hold the item being engraved: this is a thrifty project. Daniel has made everything you’ll need, from a parts list, instructions on liberating the bits you’ll need from the DVD drives, all the relevant code, wiring diagrams and tips on construction, on his website. This is an advanced project with lots of different stages to it, but it’s inexpensive and yields extraordinarily professional (and expensive-looking) results. We’d love to hear from you if you attempt your own build. |

A Semi-automated Technology Roundup Provided by Linebaugh Public Library IT Staff | techblog.linebaugh.org

Tuesday, November 26, 2013

Home-made CNC laser engraver

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment